Extended Producer Responsibility (EPR) is a policy approach that holds producers accountable for the environmental impact of their products throughout the product lifecycle, from design to end-of-life management. In India, EPR compliance has gained significant importance in recent years as the country grapples with the growing challenge of waste management. The government has introduced various EPR regulations to ensure that producers take responsibility for the waste generated by their products and work towards creating a sustainable circular economy.

This comprehensive article will delve into the different types of EPR compliances in India, the registration process, and the challenges faced by producers in adhering to these regulations. We will also explore the benefits of EPR compliance and how it can contribute to achieving India’s sustainability goals.

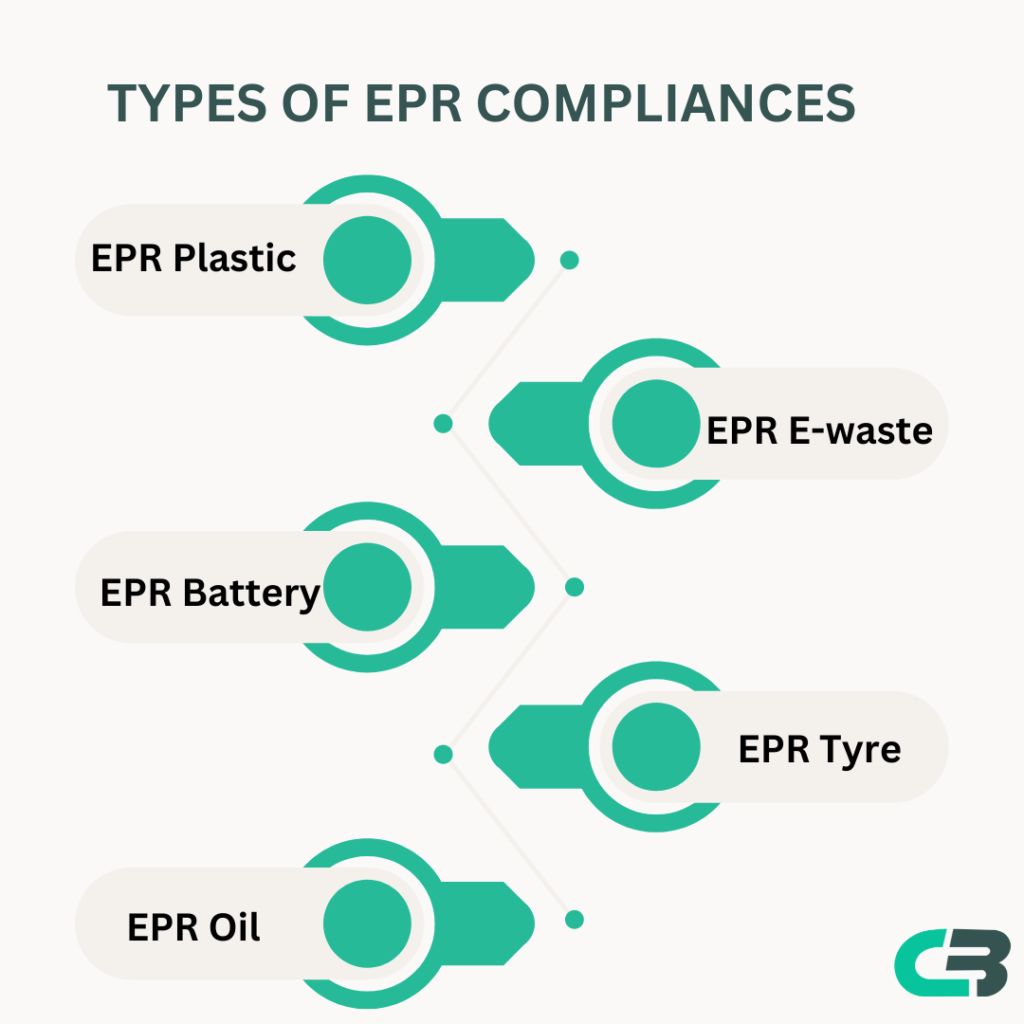

Types of EPR Compliances in India

In India, EPR compliance is applicable to various waste streams, including e-waste, plastic waste, and battery waste. Each waste stream has its own set of rules and regulations that producers must follow to ensure proper waste management. Let’s explore each type of EPR compliance in detail:

1. EPR for E-Waste

The E-Waste (Management) Rules, 2016 govern EPR compliance for e-waste in India. Under these rules, producers of electrical and electronic equipment (EEE) are responsible for collecting and managing the e-waste generated from their products. Key aspects of EPR compliance for e-waste include:

- Obtaining authorization from the State Pollution Control Board or Pollution Control Committee for e-waste management activities

- Setting up collection centers or take-back systems across various locations for consumers to return their e-waste free of charge

- Providing necessary information about these collection points to consumers through various means such as websites, toll-free numbers, or customer care centers

- Ensuring the proper transportation and storage of collected e-waste until it reaches authorized recyclers or dismantlers

2. EPR for Plastic Waste

The Plastic Waste Management Rules, 2016 (amended in 2021) outline the EPR compliance for plastic waste in India. Under these rules, producers, importers, and brand owners (PIBOs) of plastic packaging materials are responsible for collecting and managing the plastic waste generated from their products. Key aspects of EPR compliance for plastic waste include:

- Registering on the Centralized EPR Portal for Plastic Packaging (CPCB)

- Submitting an EPR plan detailing the quantity of plastic packaging to be collected, recycled, or co-processed

- Achieving the annual plastic waste collection and recycling targets set by the Central Pollution Control Board (CPCB)

- Submitting quarterly and annual reports on the progress of EPR implementation

3. EPR for Battery Waste

The Batteries (Management and Handling) Rules, 2001 (amended in 2020) govern EPR compliance for battery waste in India. Under these rules, producers of batteries are responsible for collecting and managing the waste generated from their products. Key aspects of EPR compliance for battery waste include:

- Obtaining authorization from the State Pollution Control Board or Pollution Control Committee for battery waste management activities

- Setting up collection centers or take-back systems across various locations for consumers to return their waste batteries

- Ensuring the proper transportation and storage of collected waste batteries until it reaches authorized recyclers or dismantlers

- Submitting annual reports on the progress of EPR implementation

4. EPR for Tyre Waste

Tyres, due to their non-biodegradable nature and harmful environmental effects, are subject to stringent EPR compliances. These regulations aim to ensure that the disposal, recycling, and recovery of tyres are handled responsibly.

- Collection and Recycling Targets: Producers and importers of tyres are required to meet annual collection and recycling targets, ensuring that a specific percentage of sold tyres are either collected for recycling or processed in an eco-friendly manner. These targets help reduce the accumulation of scrap tyres in landfills.

- Recycling and Recovery Certification: Companies involved in tyre recycling must obtain certification from authorized bodies to verify that the recycling process meets environmental standards. This ensures that end-of-life tyres (ELTs) are converted into reusable materials, such as crumb rubber, and not improperly discarded.

- Producer Responsibility Organizations (PROs): Many tyre producers partner with PROs, which act as third-party organizations responsible for collecting and recycling waste tyres on behalf of the producers. PROs simplify compliance for producers by managing the entire take-back and recycling process.

- Implementation of Take-back Schemes: Take-back schemes are crucial for EPR compliance, where producers and importers are required to facilitate the return of used tyres from consumers. These schemes may involve the establishment of collection points or reverse logistics systems that make tyre recycling accessible and convenient.

- Waste Tyre Management Plan: Companies are required to submit detailed waste tyre management plans that outline their strategy for collecting, transporting, and recycling tyres. These plans demonstrate compliance with the EPR regulations and highlight the company’s commitment to sustainable waste management practices.

- Annual Reporting and Audits: Regular reporting is a vital part of EPR compliance. Tyre producers must submit detailed reports on the number of tyres collected, recycled, and disposed of. These reports ensure transparency and help monitor the effectiveness of the EPR system.

5. EPR Used Oil Compliance

Used oil is classified as hazardous waste, and improper disposal can lead to significant environmental pollution. EPR compliance for used oil is designed to ensure that this waste is collected, treated, and recycled responsibly, minimizing the risks of soil and water contamination.

- Collection and Treatment Obligations: Producers of oils and lubricants are responsible for setting up systems to collect used oil from consumers and businesses. Once collected, the used oil must be processed to remove contaminants before it can be reused or disposed of safely.

- Re-refining and Recycling of Used Oil: The re-refining process is a critical aspect of EPR compliance for used oil. Producers must ensure that used oil is sent for re-refining, where it is cleaned and purified to be reused as a high-quality base oil. This not only reduces the need for virgin oil but also decreases environmental damage.

- Partnerships with Authorized Recyclers: Similar to tyres, used oil producers often partner with authorized recyclers to ensure proper collection, transportation, and recycling. These recyclers must be certified to handle hazardous waste and adhere to stringent environmental protocols.

- Producer Responsibility Organizations (PROs): Used oil producers can also work with PROs that manage the collection and recycling of used oil on their behalf. PROs streamline the compliance process and ensure that producers meet their obligations under the EPR framework.

- Annual Compliance Reporting: Producers must submit detailed reports on the volume of used oil collected and recycled each year. These reports provide transparency and allow authorities to track compliance with EPR regulations.

- Waste Oil Management Plans: Similar to tyre management plans, companies are required to submit waste oil management plans. These plans outline the company’s approach to collecting, treating, and recycling used oil, ensuring compliance with environmental standards

EPR Registration Process

The EPR registration process varies depending on the type of waste and the specific rules and regulations applicable to each waste stream. However, the general process involves the following steps:

- Obtaining necessary documents: Producers must gather relevant documents such as copies of agreements, a certificate of incorporation, a list of products, a PAN card, an identity card of the manufacturer, and a DGFT license.

- Submitting an EPR plan: Producers must submit an EPR plan detailing the quantity of waste to be collected, recycled, or co-processed, along with the strategies and timelines for achieving the targets.

- Obtaining authorization: Producers must obtain authorization from the State Pollution Control Board or Pollution Control Committee for waste management activities.

- Registering on the EPR portal: Depending on the type of waste, producers must register on the respective EPR portal, such as the Centralized EPR Portal for Plastic Packaging (CPCB).

- Submitting reports: Producers must submit quarterly and annual reports on the progress of EPR implementation, as per the specific requirements of each waste stream.

Challenges in Implementing EPR Compliance

While EPR compliance is crucial for sustainable waste management, producers face several challenges in implementing these regulations. Some of the key challenges include:

- Lack of awareness: Many producers are still unaware of their responsibilities under EPR regulations, making it difficult for them to comply with the rules.

- Establishing collection infrastructure: Setting up collection centers or take-back systems can be a logistical challenge for producers, especially those operating on a large scale.

- Data security: Proper data sanitization is crucial before disposing of electronic devices that may contain sensitive information.

- Reverse supply chain management: Managing the reverse supply chain for waste can be complex, involving multiple stakeholders such as consumers, retailers, logistics partners, and recyclers.

- Achieving collection and recycling targets: Meeting the annual plastic waste collection and recycling targets set by the CPCB can be challenging for producers, especially in the initial years of implementation.

Benefits of EPR Compliance

Despite the challenges, EPR compliance offers several benefits for producers, consumers, and the environment. Some of the key benefits include:

- Reduced waste generation: EPR compliance encourages producers to design products that are easier to recycle and dispose of responsibly, leading to a reduction in waste generation.

- Resource conservation: By promoting the reuse and recycling of products, EPR compliance helps conserve natural resources and reduces the need for virgin materials.

- Improved brand reputation: Embracing EPR compliance and demonstrating a commitment to responsible waste management can enhance a producer’s brand reputation and attract environmentally conscious consumers.

- Access to global markets: Many international markets require producers to comply with EPR regulations, making EPR compliance essential for accessing these markets.

- Positive impact on public health and safety: Proper waste management through EPR compliance helps reduce pollution and protect public health and safety.

EPR and India’s Sustainability Goals

EPR compliance plays a crucial role in helping India achieve its sustainability goals, as outlined in the Sustainable Development Goals (SDGs). By promoting sustainable waste management practices, EPR contributes to the following SDGs:

- SDG 3: Good Health and Well-Being – Proper waste management through EPR helps reduce pollution and protect public health.

- SDG 6: Clean Water and Sanitation – EPR compliance helps prevent the contamination of water bodies by reducing the amount of waste entering the environment.

- SDG 8: Decent Work and Economic Growth – EPR compliance encourages the development of waste management infrastructure, creating job opportunities in the recycling and waste management sectors.

- SDG 12: Responsible Consumption and Production – EPR compliance promotes sustainable production and consumption patterns by encouraging producers to design products that are easier to recycle and consumers to adopt responsible waste management practices.

- SDG 13: Climate Action – By reducing waste generation and promoting recycling, EPR compliance helps mitigate greenhouse gas emissions and contributes to climate change mitigation efforts.

Conclusion

EPR compliance is a critical component of India’s efforts to create a sustainable waste management system. By holding producers accountable for the environmental impact of their products, EPR regulations encourage the adoption of eco-friendly practices and the development of a circular economy. While implementing EPR compliance presents challenges for producers, the benefits of reduced waste generation, resource conservation, and improved brand reputation make it a worthwhile investment.